I-1B系列浓浆泵

I-1B浓浆泵是单螺杆式容积回转泵,该泵利用偏心单螺旋的螺杆在双螺旋衬套内的转动,使浓浆液沿螺旋槽由吸入口推移至排出口,实现泵的输送功能。结构材质型式:

I-1B型浓浆泵:壳体铸铁,传动件为一般钢材,适用于一般中性浓浆液输送。

I-1B型浓浆泵:传动件(主轴、螺杆和绕轴)为不锈钢制造,适用于一般微酸、碱浆液输送。

I-1B型浓浆泵:传动件和接角浆液的泵壳均由不锈钢制造,适用于食品、制药及腐蚀性浆液的输送。

橡胶衬套有一般耐磨橡胶,食品用橡胶和耐油橡胶供用户选择。

传动方式有电机与泵轴直接传动,电机经减速机与泵直接传动和电机经三角皮带轮与泵轴传动供用户选购。

配用电动机有一般封闭式、防爆式和电磁调速式电机。

Summary

The stud pump is that one kind of one stud type is lost the stud bush ( calling the stator ) that fortune pump and stud ( calling the rotor ) and interior surface that its major work parts are partiality spirochaetas assume the bifilar helix face . His work principle is when being moving when the electromotor drives the pump axle , and on the one hand the stud winds the axis of itself and revolves , on the other hand its again surface roll along the bush , so forming the close cavity room of pump . The stud is one week per revolution , and liquid in the close cavity pushes on forward a pitch . Along with the continuous transmission of stud , the shape method of liquid with the spiral is pressed to another close cavity from a close cavity , and finally crowds out the pump aspect.

The stud pump is the machinery of one kind of new transport liquid , and possesses that the structure is simple and work is safe and reliable and use to keep in repair convenient and goes out the merits such as liquid is continuously even and pressure is stable etc . The dense thick liquid pump of my unit production contacts altogether the metal part that the thing is expected all chooses the high quality not to become rusty the acidproof steel is made , axle material 2cr13 lines and tin uses nonpoisonous tasteless rubber and work temperature 100 ℃s attainability , available in the transport foodstuff thick liquids and the viscosity 10000 moors this calorie of contains second solid anything small and roundish or glue piece the solution thick liquid , the corrosiveness medium of suspension liquid . Extensively in the Ministry of Industry such as foodstuff , metallurgy , building , pharmacy and chemical industry etc the doors Please paying attention to : The medium difference that the stud pump uses should use the different rubber .

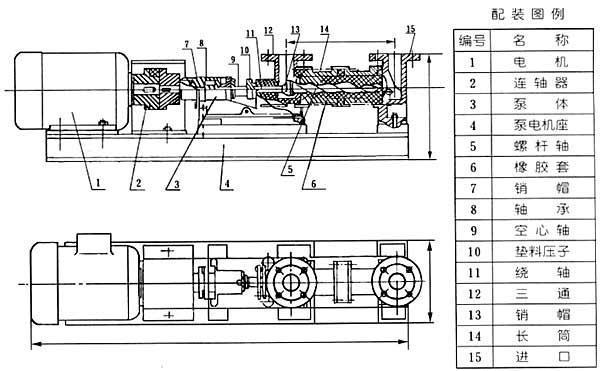

浓浆泵产品结构示意图

浓浆泵使用范围:

浓浆泵广泛应用于化工、制药、酿造、造纸、食品等单位。

1.浓浆泵可输送高浓度高粘度(<10000PaS)及含有颗粒的悬浮浆液。

2.浓浆泵输送液流稳定,无过流、脉动及搅拌、剪切浆液现象。

3.浓浆泵排出压力与转速无关,低流量也可保持高的排出压力。

4.浓浆泵流量与转速成正比,通过变速机构或高速电机可实现流量调节。

5.浓浆泵自吸能力强,液体流向由泵的旋转方向来改变,适用于管道需反、正向冲洗的场合。

6.浓浆泵运转平稳、振动、噪声小。

7.浓浆泵结构简单、拆装、维修方便。

螺杆泵(浓浆泵)是一种新型的输送液体的机械,具有结构简单、工作安全可靠、使用维修方便、出液连续均匀、压力稳定等优点。我单位生产的浓浆泵凡接触物料的金属零件均选用优质耐酸不锈钢制作,衬筒采用无毒无味的橡胶、工作温度可达120℃,可用于输送食品浆料和粘度10000泊斯卡·秒含有固体颗粒或胶块的溶液浆,悬浮液的腐蚀性介质。广泛用于食品、冶金、化工、印染、造纸、陶瓷等工业部门。

|

1

|

弯头接管

|

5

|

三通泵体

|

9

|

空心泵轴

|

|

2

|

直筒

|

6

|

石棉填料

|

10

|

泵座

|

|

3

|

橡胶管

|

7

|

填料压盖

|

11

|

销轴销帽

|

|

4

|

螺杆泵

|

8

|

绕轴

|

12

|

联轴器

|

I-1B系列浓浆泵性能参数:

|

型 号

|

理论流量

(m3/h)

|

流量

( T/时)

|

扬程

(m)

|

吸程

(m)

|

进出口径

|

转速

(r/min)

|

配用电机

(K/w)

|

工作压力

(kg/cm2)

|

|

老型I-1B1寸

|

1.8

|

1.1

|

30

|

2

|

25

|

960

|

2.2

|

3

|

|

I-1B1寸

|

2.39

|

1.5

|

50

|

2

|

25

|

960

|

1.1

|

5

|

|

老型I-1B1.5寸

|

4.8

|

3

|

80

|

2

|

40

|

960

|

3

|

8

|

|

I-1B1.5寸

|

5.2

|

3.2

|

80

|

3

|

40

|

960

|

2.2

|

8

|

|

I-1B2寸

|

8.85

|

5.6

|

80

|

3

|

50

|

960

|

3

|

8

|

|

I-1B2.5寸

|

10.6

|

6.5

|

60

|

3

|

65

|

960

|

3

|

6

|

|

老型I-1B3寸

|

15

|

10

|

60

|

3

|

75

|

960

|

7.5

|

6

|

|

I-1B3寸

|

18.1

|

12

|

60

|

3

|

75

|

960

|

5.5

|

6

|

|

I-1B4寸

|

24

|

16

|

60

|

3

|

100

|

960

|

7.5

|

6

|

|

I-1B5寸

|

36

|

25

|

60

|

3

|

125

|

960

|

11

|

6

|

|

老型I-1B5寸

|

27

|

19

|

60

|

3

|

125

|

960

|

11

|

6

|

|

I-1B6寸

|

38

|

30

|

60

|

3

|

150

|

960

|

15

|

6

|

凯美泵业公司自螺杆泵选型须知:

一、浓浆泵产品名称与型号,浓浆泵管道口径,浓浆泵使用扬程(m),浓浆泵电机功率(KW),浓浆泵电机转速(r/min),浓浆泵电压〔V〕,浓浆泵使用的吸程(m),浓浆泵使用的介质名称、比重、粘度、腐蚀性、毒性二、若已经由设计单位选定我公司的浓浆泵型号,请按浓浆泵型号直接向凯美泵业公司营销部订购。三、请尽量提供详细的产品使用要求,以便我们选型的正确性,提高使用的效率。

相关螺杆泵种类分别有:G型螺杆泵|I-1B系列浓浆泵|LQG型三螺杆泵(保温型沥青泵)

|